We recently posted a news item about improvements to a custom software application that we developed for a client involved in the midstream service industry. They manage joints of pipe from cradle to the grave, and we recently released two new modules that has extended their tracking ability even further.

Milling: Getting in from the beginning

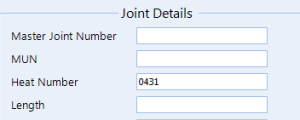

The first module allows the client to barcode joints of pipe as they are being milled. In addition, they capture the run number, coil number, and other data that helps identify that specific piece of pipe. After all of this has been completed, they commit the joint to the system.

The first module allows the client to barcode joints of pipe as they are being milled. In addition, they capture the run number, coil number, and other data that helps identify that specific piece of pipe. After all of this has been completed, they commit the joint to the system.

Welding: the second step in the process

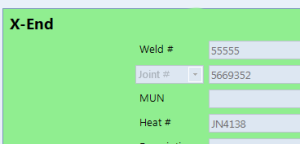

The second module follows the joint of pipe to welding. This part of the process is very important for quality control, as welds are a common point of failure in a pipeline. One employee stands on the X-End of the pipes to be welded, while another stands on the O-End. Both of their computers are connected to the same session in the system, and updates made on one end are reflected on the other.

Each worker scans the pipe to verify that the joint number is correct, and then the double jointed (DJ) weld is completed.

Afterwards, the pipe is x-ray tested from the X-End to ensure that the weld is sound. Coming additions to the module will allow the client to track this test and then follow the pipe on to coating.

Afterwards, the pipe is x-ray tested from the X-End to ensure that the weld is sound. Coming additions to the module will allow the client to track this test and then follow the pipe on to coating.

Each incremental step in the process of adding to the application allows our client to provide customers with a more and more complete view of what is happening to their property.

For more on solving business problems with custom software, check out this post. Or read about how codifying your business logic in custom software can help set your company apart…